For over 60 years, TGH has continued to evolve into one of the most recognized FAA approved (Part 145) instrument repair facilities.

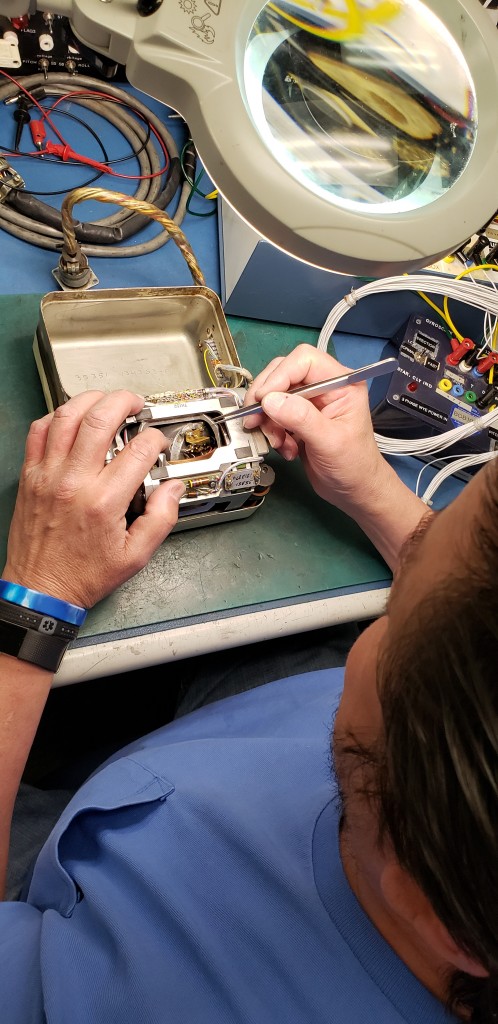

TGH Aviation upholds the highest technical standards, equipped with a professional team of skillful engineers. Our fuel technicians have decades of experience overhauling thousands of fuel flow transmitters for our military, corporate and commercial aviation customers.

TGH Aviation upholds the highest technical standards, equipped with a professional team of skillful engineers. Our fuel technicians have decades of experience overhauling thousands of fuel flow transmitters for our military, corporate and commercial aviation customers.

TGH Aviation currently operates four precision flow test stands, traceable to NIST, and are capable of calibrating flows of up to 80,000 Pounds per Hour. TGH also holds FAA approved process specifications for the calibration of fuel flow transmitters with rates up to 10,000 Pounds per Minute.

Superior customer service, industry leading expertise and years of experience have made TGH a recognized name in the aviation industry. With value and quality more important than ever, rely on the Experts at TGH Aviation to Keep You Flying!

See here for Pricing or Feel Free to Call us Monday – Fridays, 8:00 am – 4:30 pm at 1 (800) 843-4976. You click here to send us a Request for Quote online through our website.

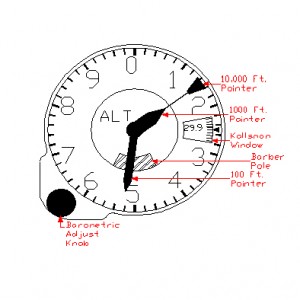

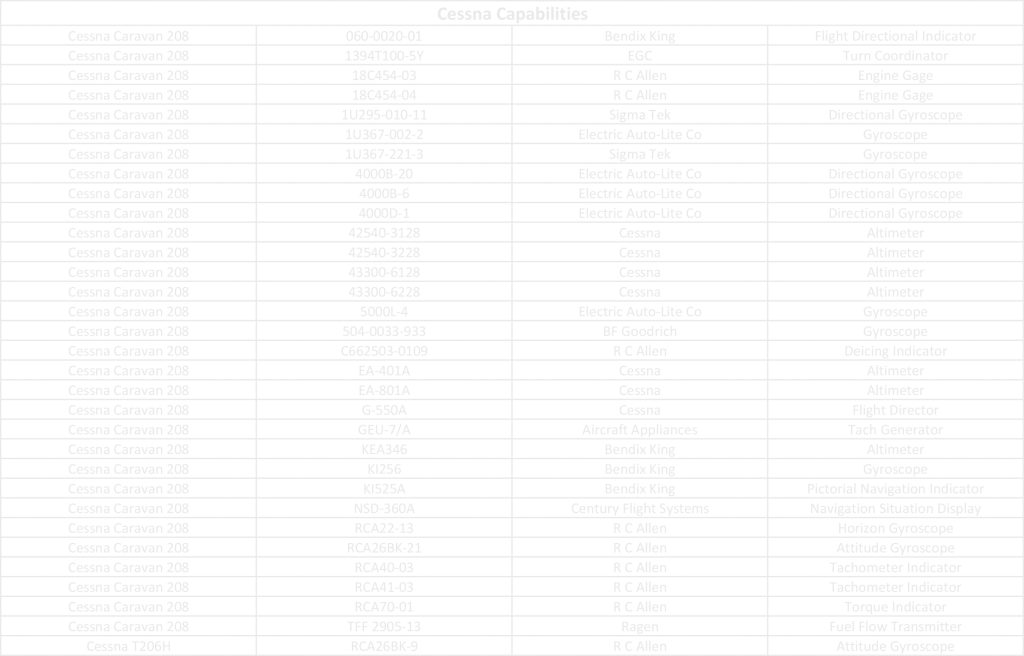

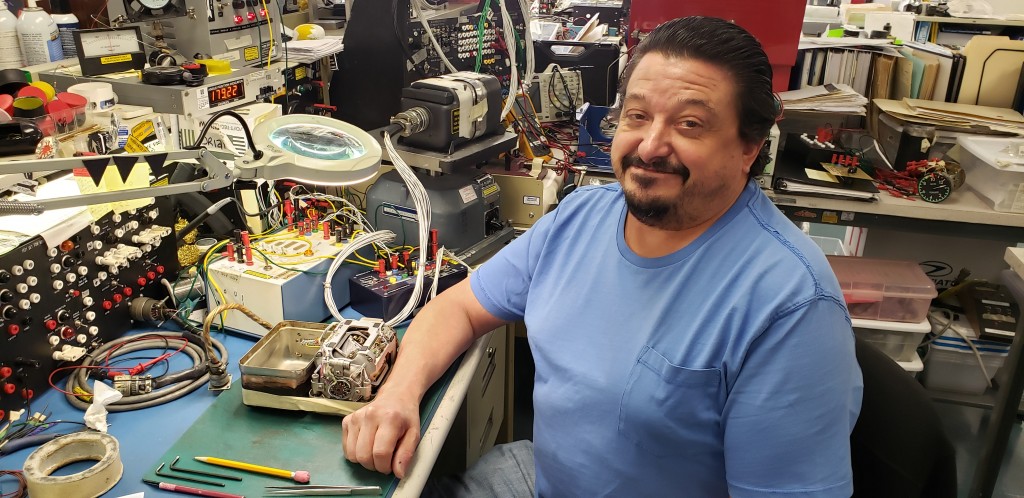

TGH Aviation offers aircraft component repair on the following Cessna Models. Below is a list of the most commonly requested repairs and does not eliminate capabilities on other instruments used in this make of aircraft. If you need an instrument repaired that is not listed below, please call our Sales Department at 1 (800) 843-4976. Veteran and Technician Brian Brown started with TGH Aviation in 2005. For the past fourteen years he has been the Repair Lead Tech working on Remote Vertical and Directional Gyros. Brian holds an Degree in Electronics and Served in the Airforce as an Airframe Powerplant Crew Chief. TGH Aviation and its employees enjoy Brian’s sardonic humor and superior overhauls and repairs. His work carries quality and precision. “Life isn’t about our routines; it’s about finding the hidden treasures of splendor in the tiny moments we have” When Brian is not at TGH, he enjoys spending time with his wonderfully large family. With seven children, a beautiful wife, many grandchildren and even a few great grandchildren, he stays busy and happy. His personal hobbies include reading and camping when he’s not taking care of his family. You can be confident in TGH Aviation to be a trusted source for all your Flight Support Systems overhauls and repairs. We employ extraordinary people with great minds and infallible skills. Our dependability is the product of our exceptional team and the mission of TGH Aviation’s FAA Repair Shop. TGH Aviation offers aircraft component repair on the following Convair Models. Below is a list of the most commonly requested repairs and does not eliminate capabilities on other instruments used in this make of aircraft. If you need an instrument repaired that is not listed below, please call our Sales Department at 1 (800) 843-4976. The phenomenal ways of an engineer’s mind facilitates the growth of man… Here at TGH Aviation, we enjoy it when our employees build life-time careers with us. George Quirk started with TGH Aviation in October, in the year of 2000. Since 2007, he has served as Chief Inspector for TGH’s FAA Repair Station. He has equipped TGH with the knowledge and know-how to deliver excellent quality and an extensive capabilities list. His tenacity keeps our team of engineers and repair techs keen and driven to deliver the best service we can provide. We appreciate George and all he does for TGH and our team. Way to go George! You’re an A+ TGH Team Member! TGH Aviation offers aircraft component repair on the following Beechcraft Models. Below is a list of the most commonly requested repairs and does not eliminate capabilities on other instruments used in this make of aircraft. If you need an instrument repaired that is not listed below, please call our Sales Department at 1 (800) 843-4976. TGH Aviation Celebrates 60 Year Anniversary Auburn, CA, March 30th, 2017 TGH Aviation, one of the most trusted and respected Part 145 Repair Stations in the industry, this year celebrates its 60th anniversary. TGH Aviation takes pride in its humble beginnings and appreciates the loyalty and dedication of both customers and employees throughout the past six decades. The company will commemorate the occasion with a number of customer appreciation specials and anniversary promotions throughout the year. In 1957 founder Emery “Claude” Oxley Senior set out with a vision to specialize in the repair of gyroscopes for General Aviation aircraft. Claude originally began working out of his home in Riverside, California before his son Emery moved the business to a small wooden building in Auburn, California and joined forces with Chief Engineer, Rich Anderson. The early years were critical to the long term success of The Gyro House, now known as TGH Aviation. The founders built a strong infrastructure for the future by developing the TGH Aviation reputation as a top quality aircraft instrument repair facility with superior customer service. Over the course of the last 60 years, TGH Aviation has vastly expanded its capabilities beyond gyroscopes, evolving into a diverse aircraft instrument repair facility that has become known world-wide. TGH Aviation now offers over 20,000 service capabilities, including the repair of primary flight instruments, avionics, aural warning systems, fuel flow transmitters, and their related indicators and refueling sensors. Today TGH Aviation is a valued supplier to the United States Department of Defense, NATO and a world-wide network of aviation maintenance facilities and parts brokers while still maintaining its legacy customer base of General Aviation pilots. TGH Aviation provides outright sales, exchange sales, avionic installations and upgrades, repair services, and holds distributorships for most of the major manufacturers of the aforementioned product lines. The company’s repair shop customer base spans all areas of the industry from general aviation, corporate aviation and commercial aviation. The customer base includes airlines, parts brokers and maintenance facilities on five continents. The past 60 years have been a hugely successful time for TGH Aviation, which now consists of a fully operational repair station, fuel lab, online pilot supply store and an avionics hangar. A veteran-owned company, TGH Aviation employs forward-thinking, growth-oriented management and all employees work to build the company reputation while improving industry presence and stature. The company is delighted to have become a part of the local community and to have had the pleasure of working with and meeting many people over the years and look forward to continuing to build on these strong relationships in the future. As TGH Aviation looks to the next 60 years the mission continues to be to provide customers with high quality products, overhauls and repairs, all delivered with premiere customer service. As one of the most trusted and respected Part 145 Repair Stations in the industry today, TGH Aviation strives to create a great customer experience each and every time. For a complete list of capabilities, go to www.tghaviation.com for more information. TGH Aviation Awarded Military Contract for Support of the United States Air Force Auburn, CA, December, 8th, 2015 TGH Aviation, based out of the Auburn Airport in Auburn CA, is proud to announce it has been awarded a multi-million dollar five year contract by the U.S. Air Force for the purpose of overhauling all Fuel Flow Transmitters, 8TJ61 Series, for the T-38 Supersonic Jet Trainers. The T-38 is the primary training aircraft for the Air Force. More than 60,000 USAF pilots have trained in the T-38 since it entered service in 1961, when it was the world’s first supersonic trainer. USAF T-38 trainers are primarily used by the Air Education and Training Command for joint specialized undergraduate pilot training (JSUPT), but the aircraft are also used by the Air Combat Command for its companion training program and by the Air Force Materiel Command to test experimental equipment. “The award of this contract extension is an affirmation by the Air Force of the extraordinary service and quality of workmanship provided by the employees of TGH Aviation,” said TGH President Richard Anderson regarding the recent contract award. For more than 56 years TGH Aviation, formerly The Gyro House, has been an industry leader in flight system support. The company exudes confidence in its ability to provide best-in-class repair, overhaul and new products for a wide range of aviation needs, with the fuel flow support being at the heart of them. TGH operates four full time Fuel Flow Transmitter calibration laboratories. All tools and test equipment utilized by TGH, for the “Return to Service” of Fuel Flow Transmitters, are calibrated, certified and traceable to the National Institute of Standards and Technology (NIST). TGH uses only quality parts that are OEM or FAA approved in the completion of repair work on Fuel Flow Transmitters. The flowmeter operates on the principle that the rotation the fuel by the constant-speed inlet impeller tends to rotate the stationary outlet turbine in an amount which is proportional to the rate of fluid flow through the device measured in pounds per hour. A constant speed motor turns at 8,000 RPM, driving the inlet impeller at 206 RPM through a reduction gear. The inlet struts and inlet impeller combine to impart a clockwise rotation to the incoming fluid, which tends to turn the outlet turbine. The outlet turbine does not rotate through a complete revolution, but as the fuel passes from the inlet impeller with a clockwise spin, it causes the outlet turbine to deflect from its neutral position against the action of a spring. The angular deflection is directly proportional to the mass rate of fuel flow. The outlet turbine deflection is sensed by a synchro transmitter which is directly coupled to it, and provides a signal proportional to the rate of flow to an indicator. TGH Aviation has a well-known reputation for their precision and innovation within the aviation industry. In addition to military aircraft repair, TGH also overhauls fuel flow transmitters for high performance aviation aircraft, corporate/commuter aircraft and large commercial aircraft. For more information on TGH aviation and their capabilities please check out their website at www.tghaviation.com. Frequently Asked Altimeter Questions The pointers on my altimeter are very jumpy and stick sometimes. The altimeter is exposed to the outside atmosphere. This includes all of the dirt and dust present in that atmosphere. Dirt and dust will get into the gears and cause them to stick and bind, the vibration from the aircraft will help the gears to overcome this problem but they will be very jumpy and become worse as the unit gets older. This unit needs an overhaul. Yes, altimeter dials can be converted, provided that the manufacturer has published a procedure for doing so. If there are no published, FAA Approved, procedures then, no, this modification cannot be accomplished. The FAA requires that the aircraft static system be tested and certified biannually. The altimeter is a part of that system. The altimeter ID plate says that it is a 35,000 Ft. altimeter, but the repair shop that overhauled my altimeter marked the unit as being certified to 30,000 Ft. Why the difference? As altimeters get older and the parts wear the unit will become inaccurate at the higher end of its range. This does not mean that the altimeter can no longer be used; it just has to be used at the lower altitude. Therefore, it will be sold only to customers who request a lower altitude unit, typically general aviation. Sometimes, if a unit is so old and worn that it can no longer be used in an aircraft then these units are sold at a discounted price for use in other than aircraft, typically people will use them in motor homes, cars, and boats. Altitude is a non-linear function. It is impossible to calibrate an altimeter to be absolutely accurate at all altitudes. Therefore, a certain amount of error is allowable. The correction card advises the users of the amount of error in a particular altimeter. As each altimeter will have its own characteristics, the error card is identified with the unit’s serial number. TSO stands for Technical Standard Order. This is an FAA document, which defines how a specific type of instrument should work in order to be considered airworthy. Altimeters manufactured by the following companies typically are manufactured to TSO standards: United Instruments, Kollsman, Garwin, and Aerosonic. Altimeters manufactured by the following companies typically are not qualified to TSO specifications:UMA & Falcon. If an instrument is certified to a TSO, it must state such on the ID plate. If it does not state the TSO on the nameplate then you must assume that it is not qualified to the TSO. What are the typical failure modes of an altimeter? A three-pointer altimeter, as its name implies, has three different pointers on the front dial. They are the 100-foot pointer, the 1000-foot pointer, and the 10,000-foot pointer. The medium length pointer is the 100-foot pointer, the shortest pointer is the 1000-foot pointer, and the longest pointer is the 10,000-foot pointer. The altimeter dial has 10 major indices numbered 0 through 9. In between each major indice are 4 minor indices. The value of these indices is dependent on the pointer being read. When reading the 100-foot pointer each minor indice equals 20 feet, each major indice equals 100 feet. When reading the 1000-foot pointer each minor indice is equal to 200 feet, each major indice is equal to 1000 feet. When reading the 10,000-foot pointer each minor indice is equal to 2000 feet, each major indice is equal to 10,000 feet. The altimeter in figure 1 is indicating 11,520 feet and is read as follows: The 10,000 foot pointer is past the 1 and not yet up to the 2 and so it is read as: 1 x 10,000 = 10,000 + The 1,000 foot pointer is past the 1 and not yet up to the 2 and so it is read as: 1 x 1,000 = 1,000 + The 100-foot pointer is 1 minor indice past the 5 and so Therefore, it is read as: 5.2 x 100 = 520 The indicated altitude is the sum of the pointers: 11,520 Figure 1: Three-Pointer AltimeterCapabilities on Cessna

Employee Appreciation | Meet Brian Brown

Corrie Vallance

Capabilities on Convair Aircraft

Employee Appreciation | Meet George Quirk

Capabilities on Beechcraft Aircraft

AIRCRAFT

P/N

MFG

NOMENCLATURE

BEECHCRAFT KING AIR 200

4000B-10

EDO

DG

BEECHCRAFT KING AIR 350

1U367-207-8

SIGMA TEK

GYROSCOPE

BEECHCRAFT KING AIR 350

1U367-232-2

SIGMA TEK

GYROSCOPE

BEECHCRAFT KING AIR 90

200-5

AIM

DIRECTIONAL GYRO

BEECHCRAFT KING AIR 90

90-380009-7

GULL

FUEL FLOW TRANSMITTER

BEECHCRAFT KING AIR 90

5000B-10

EDO

GYROSCOPE

TGH Aviation Celebrates 60 Year Anniversary

TGH Aviation Awarded Military Contract

Frequently Asked Altimeter Questions

What is wrong?Can I convert my milli-bar altimeter to InHg or vice versa?

How often does my altimeter need to be calibrated?

What is a “car” altimeter?

Along with my altimeter, I received a correction card. What is that?

What is a TSO?

How to Read a 3 Pointer Altimeter

How to Read a 3 Pointer Altimeter