Airspeeds Frequently Asked Questions

What would cause my airspeed indicator to be stuck at zero all the time?

A common cause of this is a problem with the Pitot source. If the line from the Pitot tube has disconnected, then pressure will not be applied to the instrument.

If the Pitot tube is clogged, then pressure will not be applied to the instrument.

It is common for Leaf Bugs to build nests in Pitot tubes and effectively clog them.

What would cause my indicator to be stuck at a high speed all the time?

A common cause of this is over pressure being applied to the Pitot tube. Aircraft are often washed using a high-pressure water hose. A careless mechanic may spray the hose across the Pitot tube applying high pressure to the air speed indicator. This will usually destroy the diaphragm. Units damaged in this way normally cannot be repaired and must be replaced.

Can you re-screen and/or range mark my dial?

Yes, we can. The repair department will advise you of the fee for this process. Screening dials is not done in house, this function is done at an outside vendor. The repair shop will advise the lead time. In order to ensure that the proper range marks are applied we require a copy of the airspeed specifications that are in the Pilot’s Operating Handbook.

The temperature bulb on my true airspeed indicator is broken can you fix it

No, we cannot. The bulb on a true air speed indicator is filled with gas. All of the gas escaped when the bulb broke. The bulb must be replaced. However, these bulbs are extremely expensive and extremely difficult to find.

Is the indicator you are selling me, Tso’d ?

United Instruments, Edo-Aire, Kollsman, Garwin, Aerosonic – Yes

UMA – No

If an instrument is certified to a TSO, it must state such on the ID plate. If it does not state the TSO on the name plate then you must assume that it is not approved to the TSO.

What is a TSO ?

TSO stands for Technical Standard Order. This is an FAA document, which, defines how a specific type of instrument should work in order to be considered airworthy.

What is the tolerance (accuracy) on an airspeed indicator?

Typically +/-2 (Knots or Miles per hour) up to 200 after which it is typically +/-3.

Why does it cost so much to overhaul my airspeed indicator?

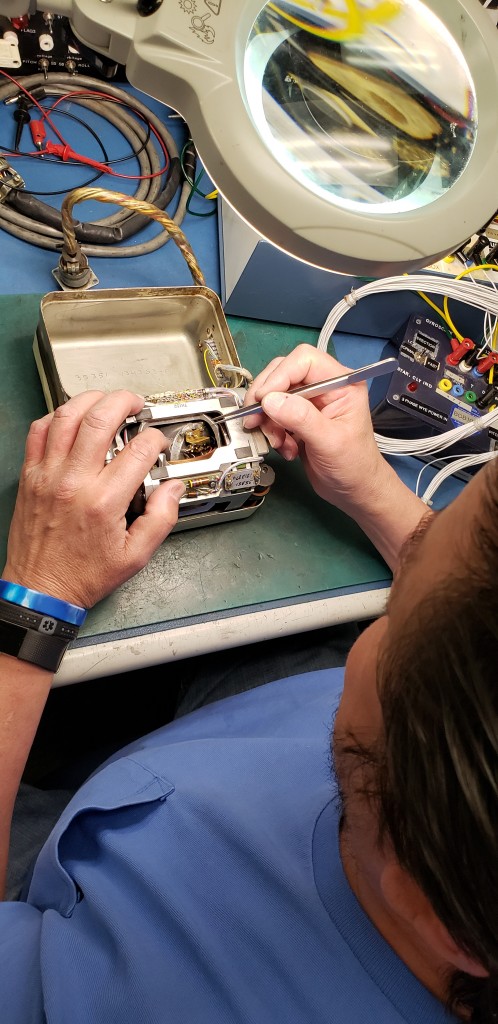

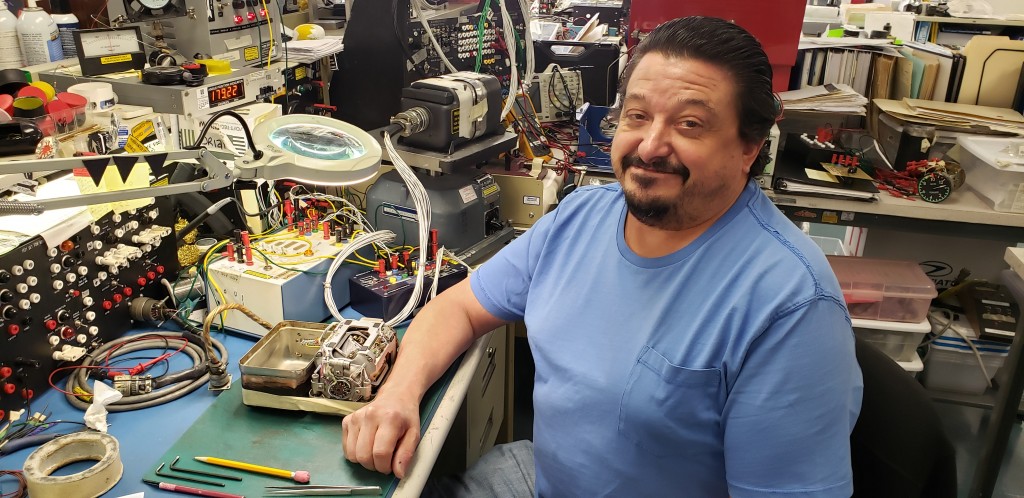

Overhauling an airspeed indicator is not as simple as you would think. A typical overhaul includes all of the following steps:

Total dis-assembly and inspection.

Determine and correct the cause of failure.

Ultrasonic cleaning of all jewels, pivots, and gears.

Reassemble internal components.

Silk-screen dial and/or range mark

Calibrate the unit to manufacturers and/or FAA specifications

Assemble unit into case.

Seal Case.

Verify calibration of final assembly.

Accomplish cosmetic touch-up.

Complete all FAA mandated paperwork and certifications.

The typical time required to overhaul an airspeed indicator can range from 1 hour for a simple unit to over 3 hours for complex units.

Calibration of an airspeed indicator is a complex process. Airspeed is a non-linear function, which must be displayed on a linear dial. There are at minimum seven calibration points that are all interactive with each other.

Thanks for taking the time to read our Airspeeds Frequently Asked Questions.